- Home

- >

- News

- >

- Industry News

- >

- Introduction To The Characteristics Of Tufted Carpets

Introduction To The Characteristics Of Tufted Carpets

1. The origin of tufted carpets

Tufted carpet originated in Georgia, USA in the 19th century. At first, it was also called turf fabric because it looked like a lawn. From the 1930s to the 1940s, tufted carpets developed from single-needle planting to row-needle planting. In the 1950s, jacquard and printed tufted carpets appeared and gradually became popular in European and American countries. Since the 1960s, tufted carpets have used chemical fibers as the main raw material, with a width of 4 to 5 m, and have become the largest and most widely used variety in machine-made carpets.

2. Brief introduction and characteristics of tufted carpet

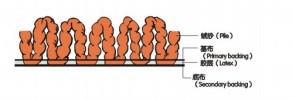

The tufted carpet is made by the tufting needle moving up and down to reciprocate to implant the pile yarn into the base fabric and then gluing and holding the pile through the back road. Wool tufted carpets are generally made of 80% wool 20% nylon or 10% wool 90% polyester; in addition, there are nylon elbow and polypropylene elbow tufted carpets.

3. Use area of tufted carpet

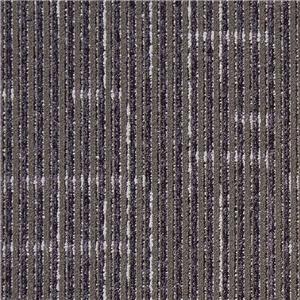

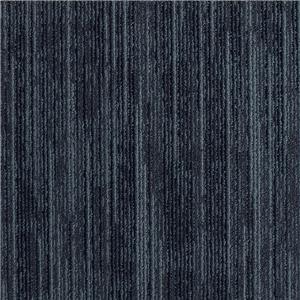

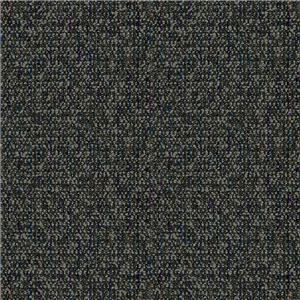

The tufted carpet patterns are mostly geometric patterns with a simple and elegant style, which are suitable for hotel rooms or residents' indoors. Nylon elbow and polypropylene elbow tufted carpets are mostly plain, and are generally used in suites and guest rooms of hotels and apartments.

4. The main process of tufted carpet

Material preparation: Spun the preheated and shaped acrylic fiber into the base cloth and various chemical fiber yarns required for the pile.

Flocking and shaping: the chemical fiber yarn is mechanically guided by the needle row to plant the pile on the acrylic fiber base cloth at a high speed to form a neat and dense loop pile or cut pile on the carpet surface.

Scrape synthetic latex or polyester adhesive on the back of the carpet, and glue the base fabric and the flocking into a solid whole.

The finishing process includes flattening the carpet surface with a shearing machine, printing on the carpet surface, pasting foam plastic backing such as styrene butadiene rubber or polyurethane or jute cloth backing on the carpet back, fluffing and finishing the carpet surface with steam, etc.

5. The composition of the carpet surface of the tufted carpet

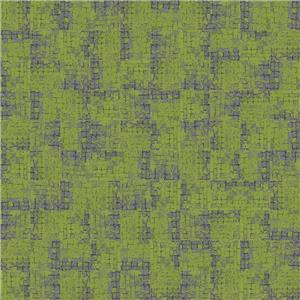

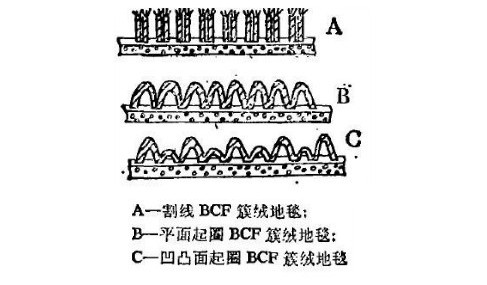

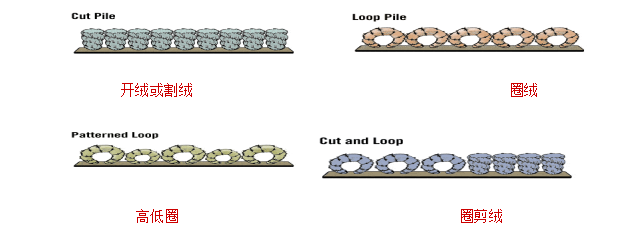

The tufted carpet is mainly composed of three parts: the surface yarn, the first backing and the second backing. The tufting of noodle yarn is divided into three types: cut pile, flat loop and concave-convex loop (as shown below)

6. The carpet surface treatment method of tufted carpet (see the picture below)

7. Specifications of tufted carpet

8. Standard width: 3.66 meters, 4 meters.

9. Standard roll length: 25 meters, can be specially ordered according to customer requirements.

10. Needle pitch: 1/8” (315 pieces/m), 1/10 (394 pieces/m).

11. Proofing time and custom time: Proofing time: 15 days, custom time: about 30 days.

12. 8. Where to use tufted carpets

13. Tufted carpet: The pattern is modern, the color is elegant, the variety is rich, and the pile is full, especially the varieties of pile, high cut low loop, embossed loop pile jacquard, etc. It is the trend representative of the family pile carpet. It is suitable for meeting rooms, apartments, hotel rooms and other places.